High pressure fire pump are used by firefighters to apply water mist systems. The high pressure and flow of these pumps allows the firefighter to move more quickly through the building.

When selecting a fire pump, you need to consider both gallons per hour and head pressure. You should also look at the factory test curve and ensure that the power peaks and then falls.

UL & FM Approvals

Fire pumps must withstand rigorous, harsh test processes to receive the UL and FM markings. This testing is incredibly important, as it ensures that the fire pump will work when needed. This type of certification guarantees that the fire pump will meet the performance, safety and quality requirements, which are all designed to protect property.

UL and FM approvals are internationally recognized standards. They are the gold standard for quality, efficiency and reliability. It is not uncommon to see the UL or FM logos on major products at major firefighting trade fairs. In fact, the NFPA 20 standard for fire pumps and packages specifies that only UL or FM approved fire pumps can be used.

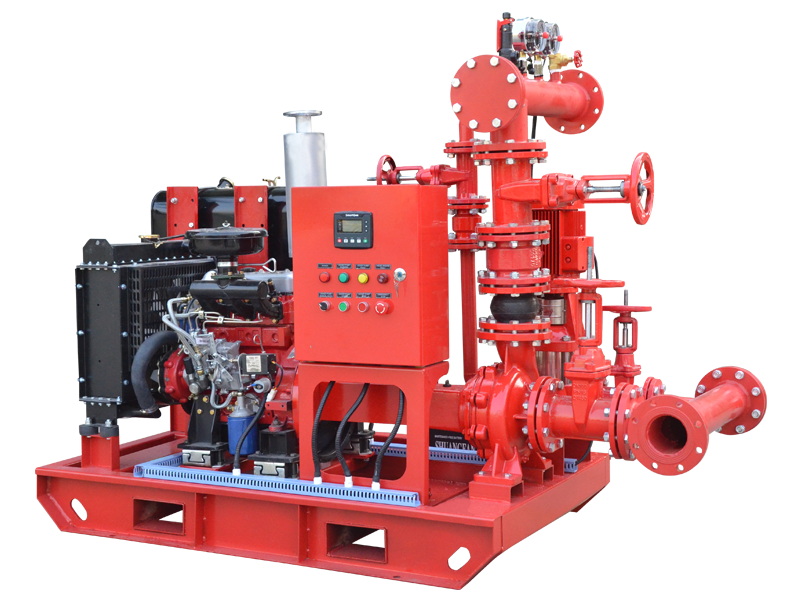

A UL fire pump can be powered by an electric motor or by diesel engines. The engine power is transmitted to the fire pump through a right angle gearbox. This type of fire pump can handle a wide range of water pressure and flow rates.

Some fire pumps with higher flow rates may require a UL or FM certificate. This requires that the impellers, wheel wear rings, pump nuts, casing heat rings or in-pump bolts are made of corrosion-resistant materials. Also, a drain plug must be located directly above the pump body. The pump must have a stuffing box and the bearings should have a working capacity of 5000 hours at maximum load.

Efficiency

The fire pump is a crucial piece of any sprinkler system because it is what creates the necessary pressure to operate the system. It is important that this pressure is as high as possible without causing excessive wear on the system components. A high-efficiency pump design is essential to achieving this. Choosing a positive-displacement pump is generally the best choice, as these designs are power-efficient.

In order to select the right fire pump, it is important to look at the factory-certified performance curve. This will show the maximum net pressure that the pump can achieve at its rated flow, along with the required horsepower and head pressure. It is important to note that the rated net pressure usually only occurs at the rated flow, meaning that the pump will produce less pressure at lower flows.

It is also important to consider the hydraulic calculations for the system from the point where the water supply will be to the discharge flange of the fire pump, taking into account any elevation change that may occur. This will help ensure that the correct pump is selected and that the system will be able to operate at its intended capacity.

Another consideration is the type of controller that will be used on the fire pump. There are several different styles of controllers, and each has its pros and cons. Often, electrical engineers will recommend a soft start controller on the fire pump to reduce the immediate power draw from the backup generator and increase the amount of time that the fire pump can be run on backup power before shutting off.

Safety

Fire protection systems require a high pressure in order to deliver water to sprinkler heads and meet system design demands. Fire pumps are necessary when the local municipal water supply can’t create enough pressure to satisfy system demands, such as in tall buildings or systems with a requirement for a higher terminal pressure at the fire sprinkler.

When sizing a fire pump it is important to consider both the maximum suction and discharge pressure ratings. A higher rated head or nozzle allows the pump to reach higher velocities, but will reduce the rated pressure. For this reason it is recommended that the nozzle pressure be sized 20′ higher than the pump (suction) rated head.

The maximum pressure of the pump is also dictated by the minimum pipe diameter required between the test header and the pump discharge flange, this minimum requirement is set by NFPA 20. To maximize the life of a fire pump it is important to size the pipe correctly based on a system demand analysis performed by a qualified professional.

During the installation of a fire pump it is important to remember that NFPA 20 has many valuable requirements, which should be followed as closely as possible to ensure that the fire pump will perform properly in an emergency situation. The installation of a fire pump and system should always be completed by a qualified fire safety professional to ensure that the building is protected in the event of a disaster.

Maintenance

Fire pumps provide water flow at higher pressure for fire sprinkler systems, and they must be inspected and tested on a weekly, monthly, and annual basis. A professional company like Avalon Fire Protection offers essential fire safety services in the Orange County area, including fire fighting pumps, and their team can perform inspections, tests, and maintenance on these important systems to ensure they are ready for use.

Tests on fire pumps involve using a set of specialized tools and procedures. Unlike regular business equipment, which can usually be maintained by in-house staff, fire pumps require special knowledge and training to inspect, test, and maintain. It is important that these tasks are done by a trained technician, and the results are documented correctly.

To test a fire pump, it is necessary to have a large number of test hoses and a flow measuring device that can handle the 150% of the rated flow of the pump (for high gpm rating). The test also involves checking that the water supply system has the ability to deliver a full volume test and that the bypass line for the fire pump is functioning properly.

For a diesel fire pump, it is recommended that a no-flow test be performed on a weekly basis. This can be accomplished by connecting a Venturi style flowmeter to a normally closed bypass valve on the suction side of the pump casing and opening the bypass valve. The pump should run for at least 10 minutes during this test to verify that the circulation relief valve is working as it should.