Explosion proof electric actuators are ideal for use in hazardous environments. They are suitable for a variety of valve types and provide a safer alternative to fluid-operated systems.

They operate using utility power to move the valve into its normal operating position and then compress a fail-safe spring mechanism. They reset to a safe position when power is lost and are great for remote locations with limited power availability.

Safety

Safety is essential when working in dangerous environments. Fortunately, explosion proof electric actuators are designed to protect your employees and equipment. They have a flameproof housing and double seals on the power shaft to prevent sparks. They are ATEX certified and suitable for use in hazardous gas, dust, or vapour environments.

Unlike conventional electrical actuators, which require continuous sources of electricity to operate, explosion-proof electric actuators have fail-safe mechanisms that automatically revert to a safe position if power is lost. This is especially important in hazardous environments, where a power outage can cause equipment damage and create unsafe conditions.

Moreover, the explosion-proof electric actuator is also equipped with a hand wheel for manual operation in case of emergency. Its explosion-proof features make it ideal for use in oil, chemical, power plant, paper making, and shipbuilding industries. Its hard aluminum alloy and anodizing finish with polyester powder coating provide high resistance to corrosion. Moreover, its compact design makes it perfect for quarter-turn applications such as ball valves and butterfly valves.

Durability

An explosion-proof electric actuator is a great choice for use in volatile environments. These actuators feature fail-safe mechanisms to revert to their last known position in case of power failure. They also contain a series of circuits designed to minimize spark and thermal effects, making them ideal for hazardous conditions.

There are many different performance metrics that can be used to evaluate an actuator. The most important ones are torque and speed. Torque refers to the actuator’s capacity to exert force, while speed measures the actuator’s movement.

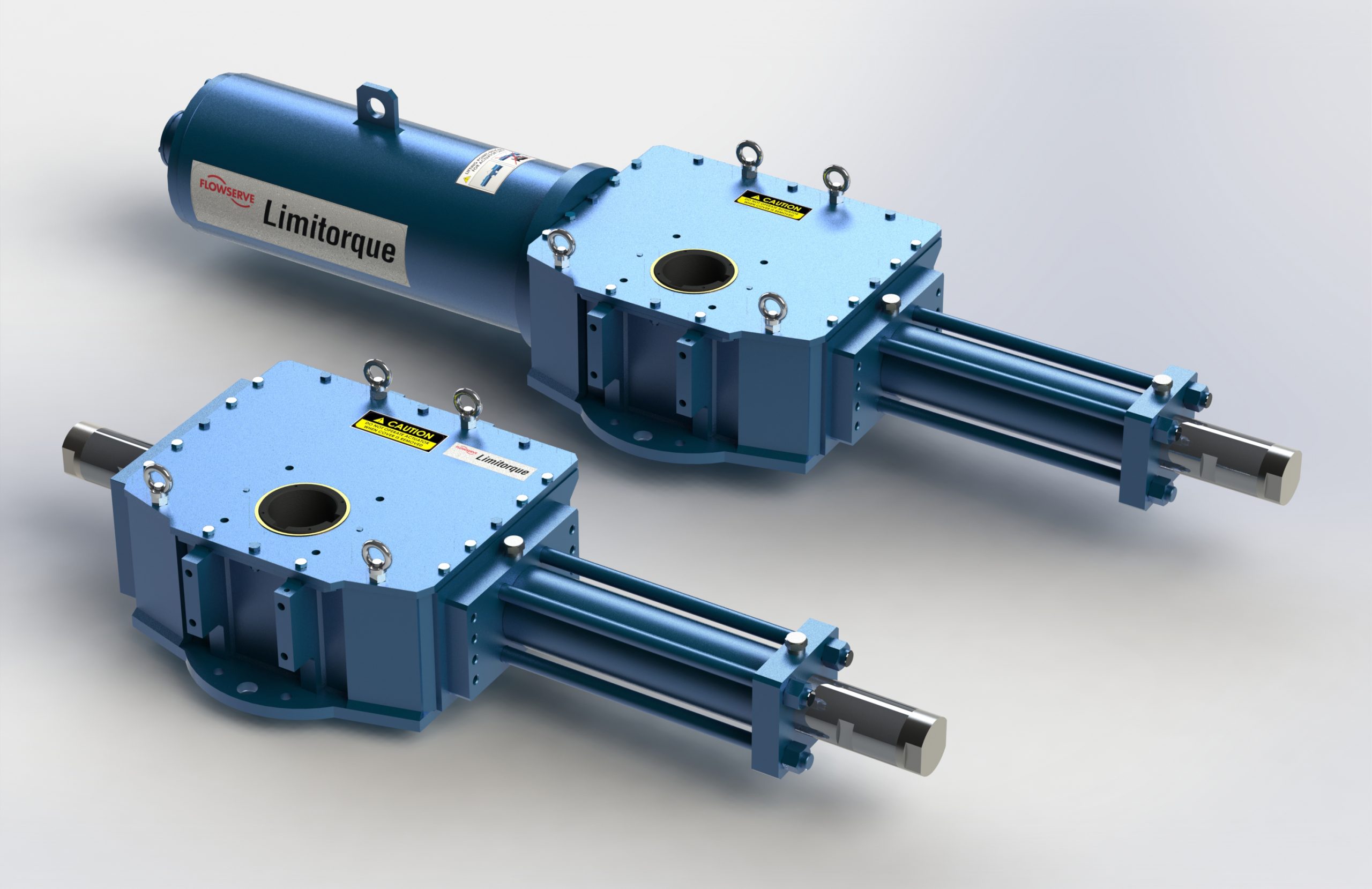

BERNARD CONTROLS has supplied more than 30 explosion proof electric actuators from its STX and SQX ranges for the oil storage installation of Raffinerie du Midi – GPSPC in Saint-Pierre-des-Corps (North France). These linear actuators are ATEX-approved for Zone 2 gas and dust. The actuators are equipped with a double worm gear system that efficiently transmits large torque. In addition, they are very reliable and durable, with a long life.

Efficiency

An explosion proof electric actuator offers command and control over the opening and closing of industrial valves and dampers. They are used in hazardous environments to provide safe and precise operation. They are also designed to maximize efficiency and long-term performance.

These explosion-proof actuators can be equipped with a battery backup that will revert to the desired position if power is lost. This prevents damage to equipment and injuries to people. Several models of this type of actuator are available, including field-selectable fail open and fail closed settings.

These actuators are ideal for quarter-turn operating applications like ball valves and butterfly valves. They have a compact design and are easy to install. They are made of hard aluminum alloy with anodizing and polyester powder coating, making them durable and corrosion resistant. They are also lightweight. This makes them a great choice for sensitive, hazardous environments. They are available in a wide variety of voltages to suit your needs.

Cost

Explosion proof electric actuators are cost-effective and easy to use. They are certified to meet US, European, and Chinese explosion proof standards and are designed for safe operation in environments with flammable gases. They are typically used to automate quarter turn valves and can also be applied to butterfly valves or dampers. They are also equipped with a visual position indicator and manual override.

They come in a wide range of sizes and are compatible with many different supply voltages and two-position control options. Some have a fail-safe mechanism that reverts to the safe position in case of failure, making them ideal for hazardous locations.

Besides being explosion-proof, the actuators are also weatherproof and have dual conduit seals to prevent sparks or heat from reaching the power shaft. They are ideal for applications that require a reliable operation in potentially explosive atmospheres such as oil and gas facilities, chemical/pharma plants, and water treatment facilities. They are also UL, ATEX, and IECEx compliant.